Get unique, complex parts easily. No matter your requirements, Master Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Master Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

With over 75 years of manufacturing experience, Master Spring is a proven U.S. supplier of wire forms and coil springs for the commercial luminaires industry.

We manufacture LED downlight torsion springs, retainer clips in PAR lamps, diffuser spring clips, downlight lens access retainer springs, LED optic hold springs, retainer clips for MR16 LED egress lamps, and extension springs to secure doorframes to lighting fixtures.

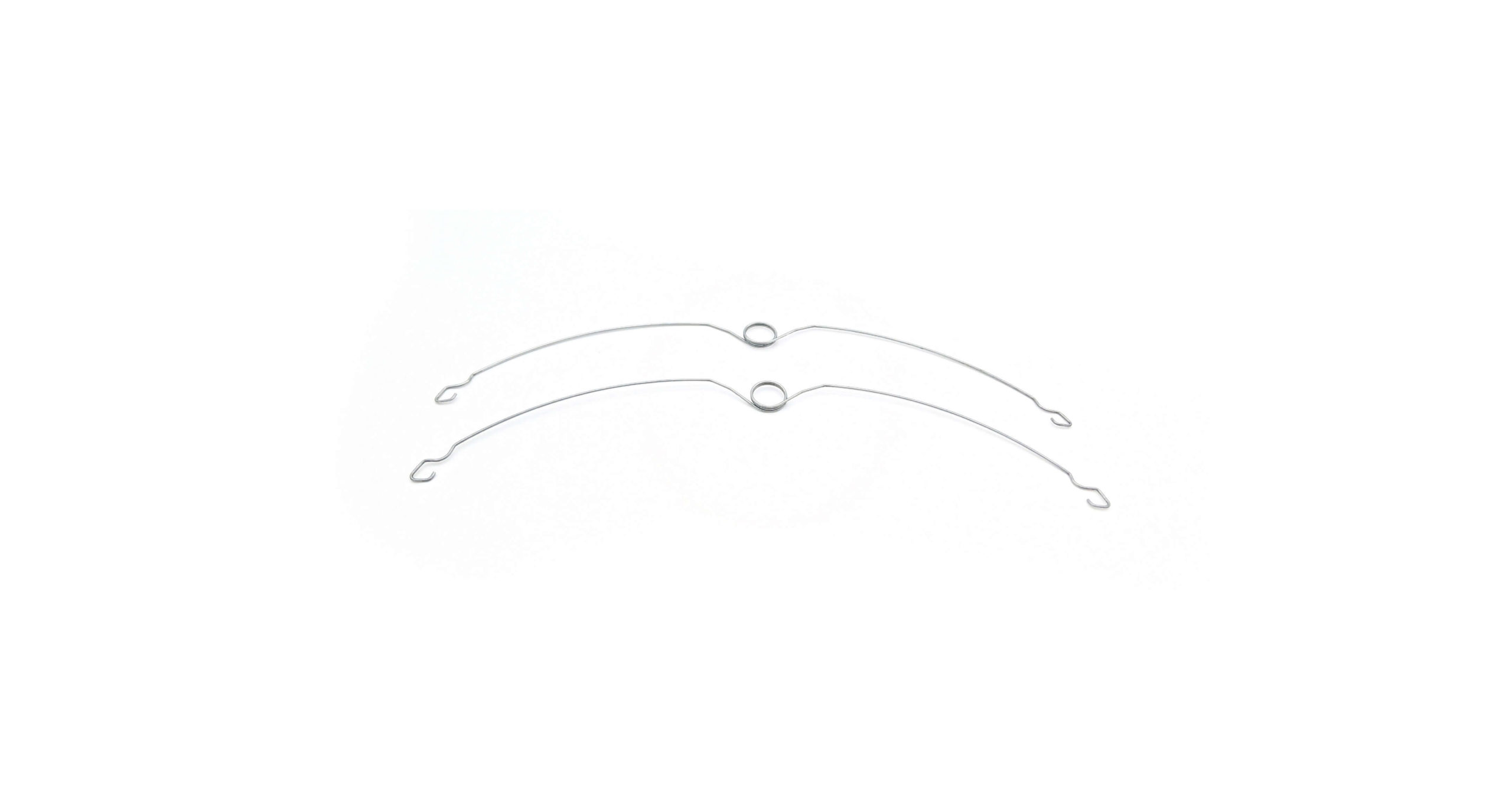

Downlight Torsion Springs

Part Names: LED downlight torsion spring, LED torsion spring, galvanized torsion spring

Industry: Commercial lighting or luminaires

Application: Torsion spring secures LED module to housing of downlight and wall wash luminaires

Material: Pre-plated galvanized music wire

Special Features: Assorted ends on long torsion legs; packed to prevent tangling during shipping

Recessed Downlight Torsion Spring

Part Names: Galvanized torsion spring, LED downlight torsion spring, LED torsion spring

Industry: Commercial lighting or luminaires

Application: Torsion spring secures LED module to housing of downlight and wall wash luminaires in retail, hospitality, and commercial spaces

Material: 0.048” pre-plated galvanized music wire

Special Features: Multiple, close bends at the end of each long torsion leg; bagged in small quantities to prevent tangling during shipping

Retainer

Part Names: Stainless steel retainer clip, swaged wire retainer clip, retainer wire form

Industry: LED lighting fixtures for entertainment, film and broadcast, and architectural applications

Application: Retainer clip holder in parabolic aluminized reflector (PAR) lamp

Material: 0.113” stainless steel 304 ¼ hard wire

Special Features: Swaged in-line

Retainer Clip

Part Names: Stainless steel retainer clip, MR16 LED wire form clip

Industry: Commercial lighting

Application: Retainer clip for MR16 LED exit and emergency lamps

Material: 0.041” stainless steel 302 wire

Special Features: Packed on tack board to prevent tangling

Lens Stop Spring

Part Names: Spring clip, galvanized wire clip, diffuser spring clip, wire form clip

Industry: Commercial lighting

Application: Spring holds diffuser in the housing

Material: 0.059” galvanized music wire

Special Features: Layer packed at machine to minimize tangling

Retainer Spring

Part names: LED retainer clip, lens retainer spring, galvanized wire retainer, downlight wire form retainer

Industry: Commercial lighting

Application: Lens access retainer spring in round LED variable beam downlight

Material: 0.051” galvanized music wire

Special Features: Assemble and heat shrink three black rubber sleeves on retainer clip

Load More

Need a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote..