Get unique, complex parts easily. No matter your requirements, Master Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Master Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

With over 75 years of manufacturing experience, Master Spring is a proven U.S. supplier of wire forms and coil springs for the construction power tool industry.

We manufacture wire forms and springs for construction power tools, cordless and pneumatic finish and brad nailers, framing and roofing nailers, staplers, hammer tools and plumbing in-pipe camera equipment.

Utility Hook

Part Names: Reversible belt hook, belt clip, adjustable rafter hook, suspension hook, hang hook, utility hook wire form

Industry: Construction power tools

Application: Belt or rafter hook for hanging construction power tool

Material: 0.250” annealed C1065 cold-rolled steel

Special Features: Reduce wire diameter, chamfer, thread, swage (press), austemper harden, electroless nickel plate, nylon thread lock

Workpiece Contact Probe

Part Names: Contact trip, precision point tip, contact tip, work contact element, nose piece, no-mar tip, workpiece contact probe

Industry: Construction power tools

Application: Workpiece contact probe presses against work surface to aim nail and allow nailing gun to fire

Material: 0.156” annealed C1065 cold-rolled steel

Special Features: Reduce wire diameter, chamfer both ends, thread, notch (press), austemper harden, black oxide finish

Trigger Spring

Part Names: Torsion spring, trigger spring

Industry: Construction power tools

Application: Torsion spring for nailing gun trigger

Material: 0.032” pre-plated galvanized music wire

Special Features: Special packed 500 pieces per bag

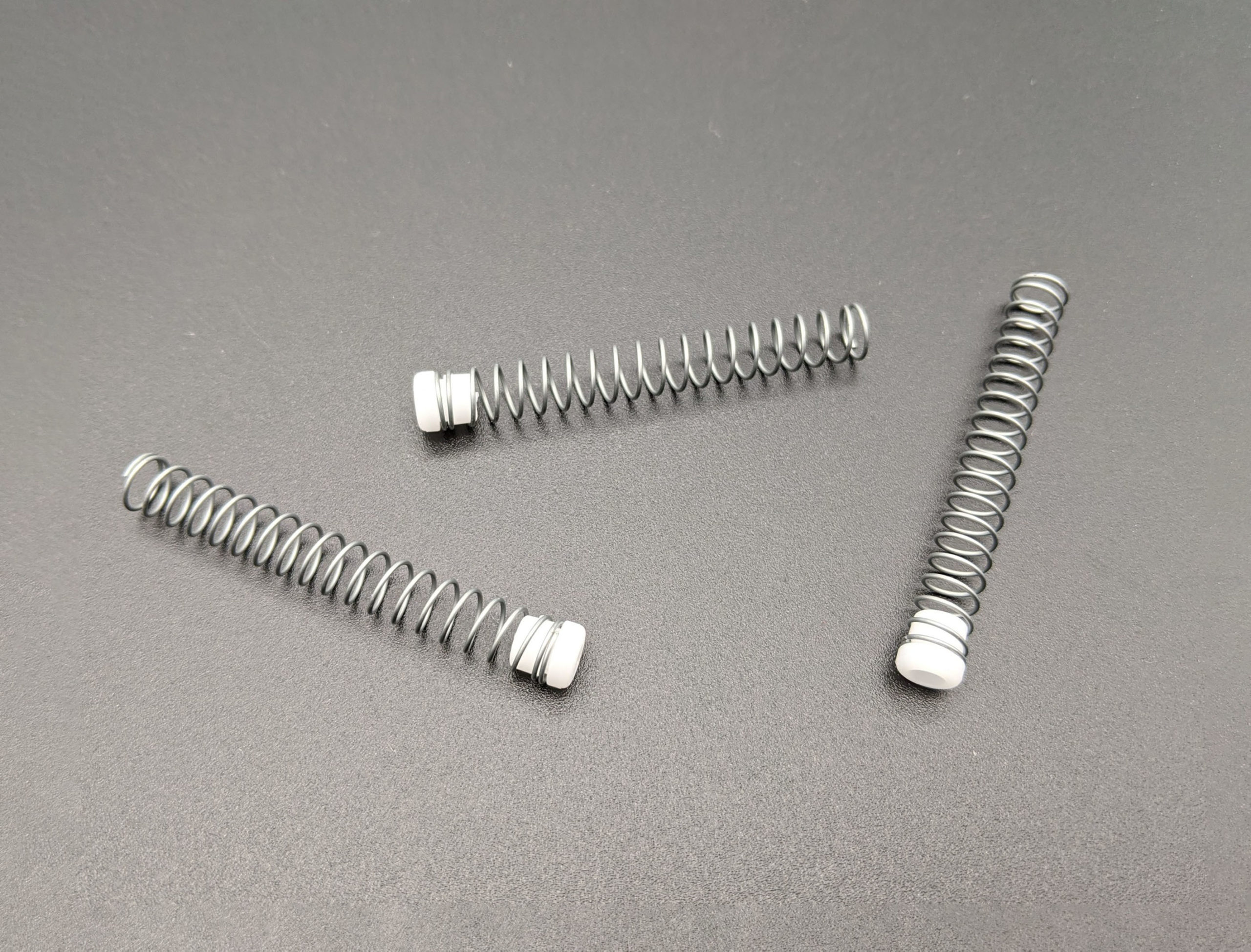

Yoke Spring Guide Assembly

Part Names: Yoke spring, CENG compression spring

Industry: Construction power tools

Application: Compression spring for yoke in combustion chamber of nailing gun

Material: 0.020” pre-plated galvanized music wire

Special Features: Closed ends and not ground, plastic spring guide is assembled to end of spring, packed 500 pieces per bag

Chamber Return Spring

Part Names: Return spring, chamber return spring, CEG compression spring

Industry: Construction power tools

Application: Compression spring returns chamber to starting position after nailing gun

Material: 0.030” phos music wire

Special Features: Closed ends and ground, electroless nickel plate, packed 500 pieces per bag

Magazine Latch Dual Torsion Spring

Part Names: Magazine lock spring, magazine latch spring

Industry: Construction power tools

Application: Double torsion spring for magazine latch release on nailing gun

Material: 0.058” hard drawn bright wire

Special Features: Special packed 250 pieces per small box

Load More

Together We Achieved

Customer Wire Form Challenge

The wire form appears simple at first glance, but requires many operations to manufacture. One end of the wire is machined to a smaller diameter so that the final diameter after thread rolling is the same as the original wire diameter. The sharp ends are then broken or chamfered. The middle of the wire is swaged to form teeth that can grip into a wooden rafter. There are multiple bends, including an offset bend to both sides of a loop, as well as a bend in the end that butts against the other side. The bending is a complicated operation, but our top-notch CNC wire-bending machinery and engineers can handle it.

Master Spring Solution

In order to compete against this customer’s overseas component suppliers, we removed as much labor from the production process as possible. We automated multiple operations to create a flexible production cell that includes a CNC wire former, a turndown, chamfer, thread and mill machine, a press and a robot. The production cell starts with a coil of wire and ends with a formed belt hook that includes the threads and swaged wings. Three proven, local vendors provide the required special heat treating, electroless nickel plating and nylon patch application to the thread.

Results

With Master Spring’s wire forming knowledge, automated production process and strong customer support, our OEM customer receives better quality wire forms and springs, shorter lead times and competitive pricing. We offer a better value than any overseas supplier.

Together We Achieved

Customer Torsion Spring Challenge

The customer needed a double torsion spring that not only worked but would stay fastened to the magazine latch-release assembly. The magazine latch release spring’s legs each had one 90-degree bend and butted against each other through the center hole of its plastic-button mating part. One leg of the latch-release spring would occasionally dislodge from the assembly if the other leg end pushed it out. The customer needed a magazine latch-release double torsion spring that stayed in place once installed. They did not want to make a change to the plastic-molded mating part.

Master Spring Solution

Upon seeing how the torsion spring’s leg ends easily moved back and forth out of the hole of the magazine latch-release button, our engineer and skilled machine technician realized the problem. The legs were too far from the button’s center hole. They determined where bends were needed in each leg to bring the torsion spring legs closer to the button’s center hole. Our skilled machine technician quickly programmed the design changes and sent samples to our customer the next day.

Results

This double torsion spring is a great example of Master Spring’s design expertise. By putting extra bends in each leg, we designed and manufactured a double torsion spring that fit closer to the assembly so the magazine latch-release spring would stay secure to the button.

Need a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.