Get unique, complex parts easily. No matter your requirements, Master Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Master Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

With over 75 years of manufacturing experience, Master Spring is a proven U.S. supplier of wire forms and coil springs for the filters industry.

We manufacture wire forms and springs for fuel dispenser filters, industrial vacuum pumps, hydraulic filters, flex tube filters, diesel exhaust fluid filters and vent caps for fuel storage tanks.

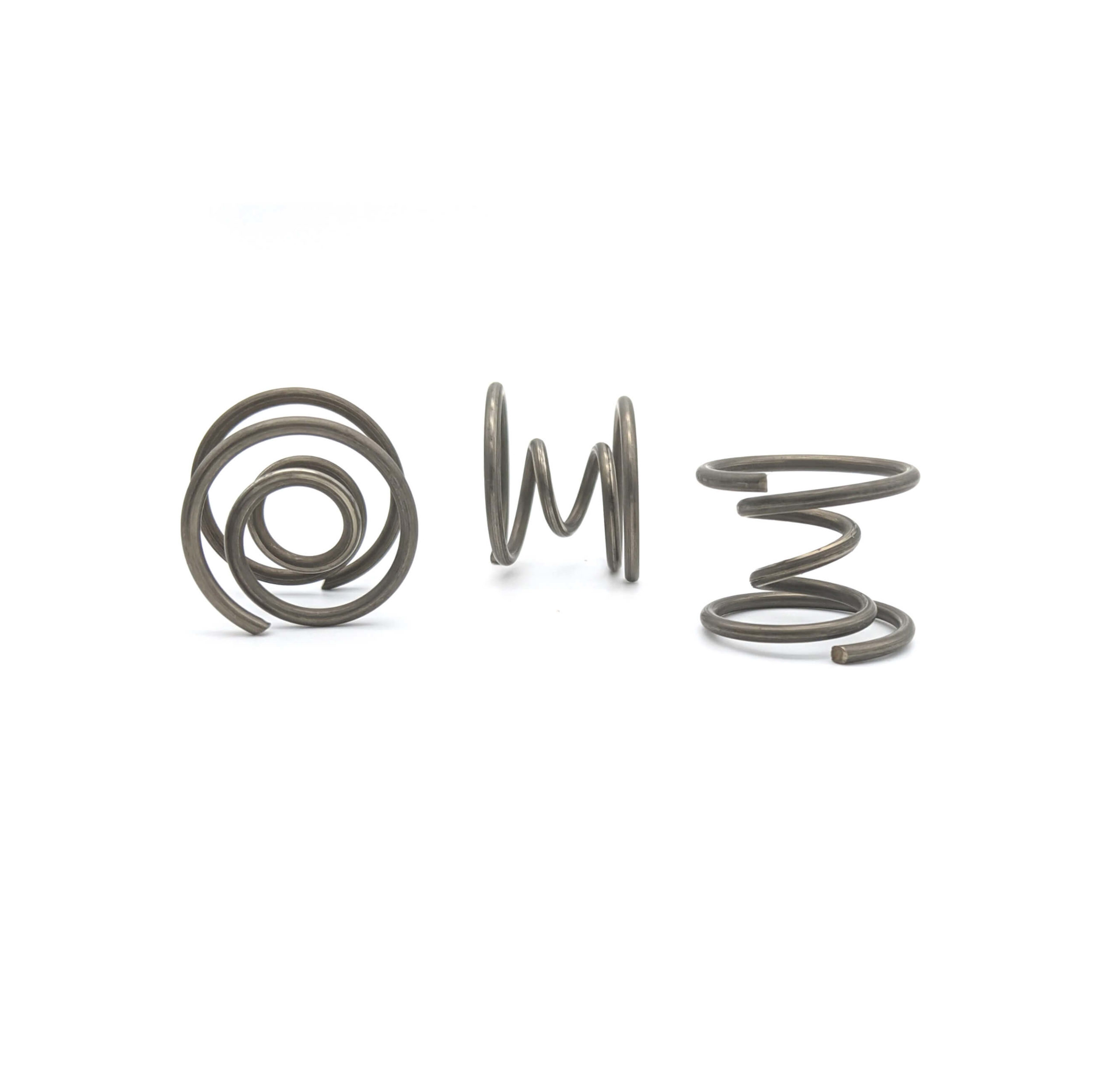

Fuel Dispenser Filter Spring

Part Names: Hourglass compression spring, fuel filter spring, petroleum filter canister coil spring

Industry: Filters for the petroleum, industrial, agricultural, heavy duty, and biofuel markets

Application: Spring holds media in place inside canister

Material: 0.099” hard-drawn bright wire

Special Features: Hourglass-shaped spring; no overlap on ends; packed 1,000 springs per box

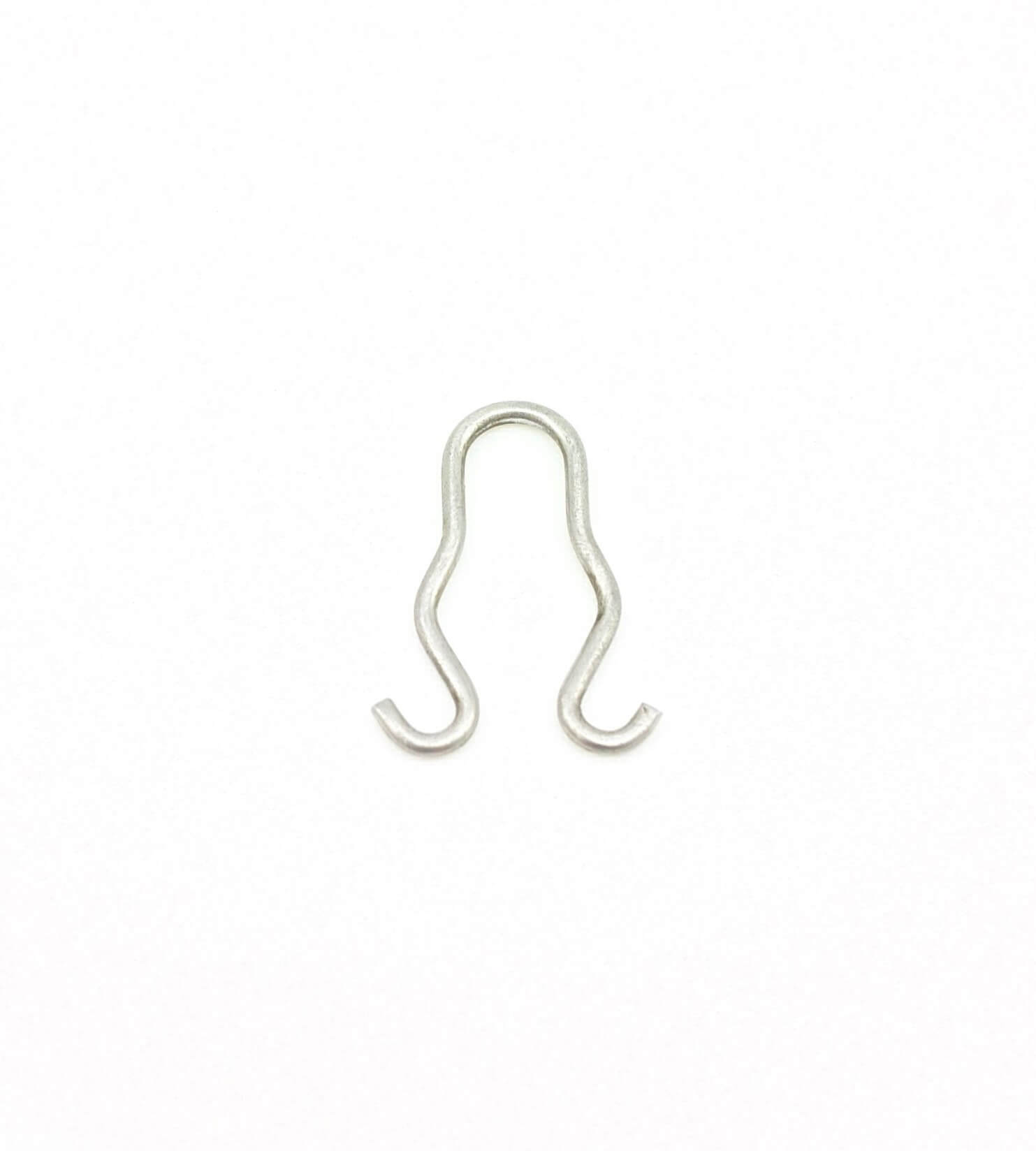

Hairpin Clip

Part Names: Stainless steel wire clip, filter hairpin clip

Industry: Diesel Exhaust Fluid (DEF)/Urea sensing solutions and DEF/Urea delivery modules for automotive, on-highway truck and off-highway applications

Application: Hairpin clip for filter in heater module of Temperature Ultrasonic Level and Concentration (TULC) sensor for SCR Diesel Exhaust Fluid (DEF) tanks

Material: 0.041” stainless steel 302 wire

Special Features: Clean cut and free of oil

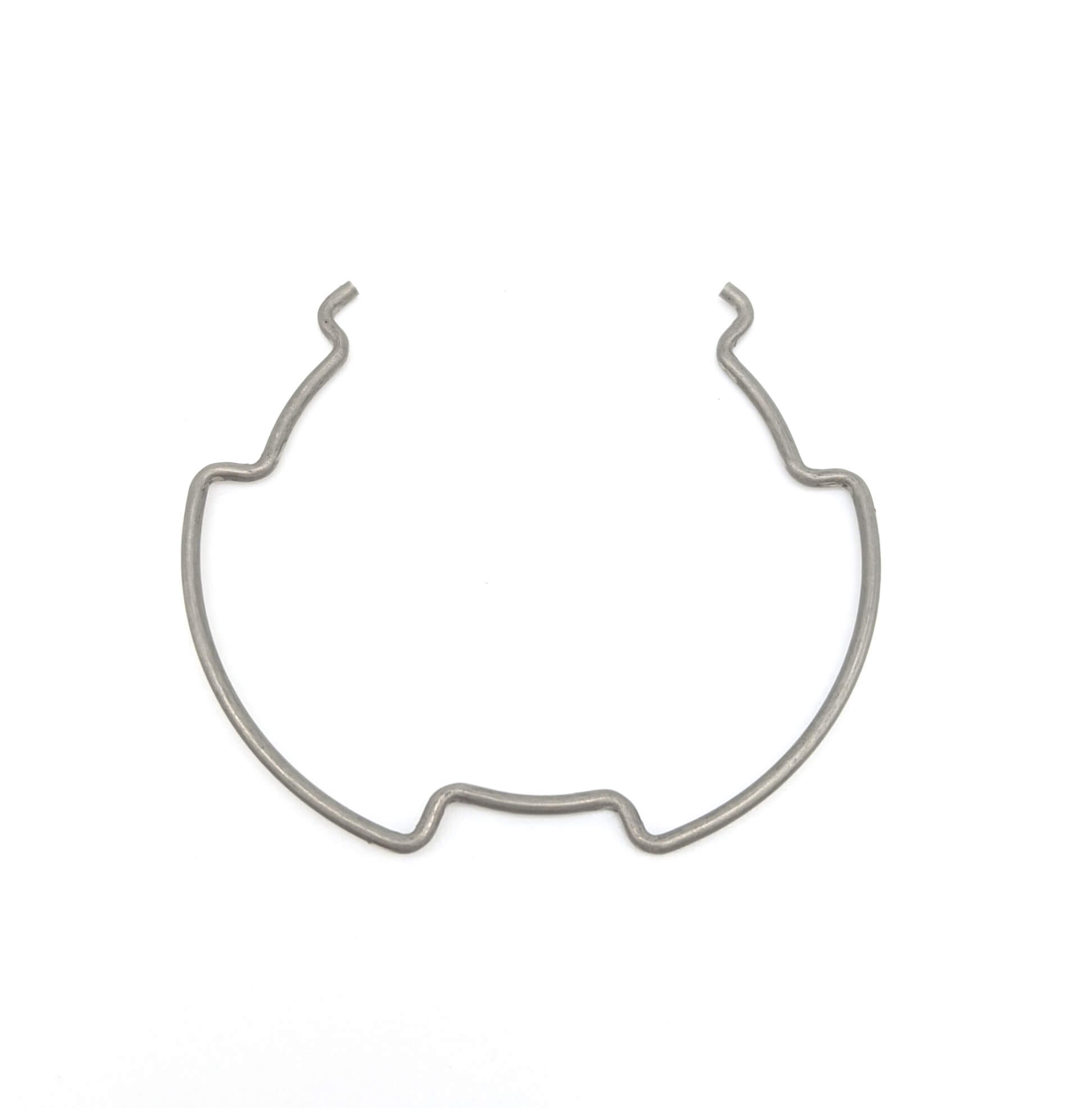

Retainer Clip

Part Names: Stainless steel clip, wire clip, stainless steel retainer clip

Industry: Filters for petroleum, industrial, agricultural, heavy-duty and biofuel markets

Application: Retainer clip used in vapor control cap on above ground farm tanks, fuel transfer tanks and oil tanks

Material: 0.058” stainless steel wire

Special Features: Layer-packed on cardboard sheets to minimize tangling

Wire Spring Latch

Part Names: Hold-down clamp, cover latch, wire form clip, retaining spring clip, filter latch, wire spring latch

Industry: Inlet filters, liquid separators, and vapor condensers for industrial vacuum pumps

Application: Wire form latch fastens top housing to bottom bucket

Material: 0.090” stainless steel 302 wire

Special Features: Two wire form pieces assembled in-line on wire forming machine to create latch

Handle

Part Names: Filter handle, wire handle, hydraulic filter handle

Industry: Hydraulic filters

Application: Handle for top of hydraulic filter

Material: 0.105” galvanized music wire

Special Features: Layer-packed on cardboard sheets to minimize tangling

Together We Achieved

Customer Compression Spring Challenge

Our customer was using a standard coil compression spring. To reduce the amount of material needed to make the spring, the fuel filter supplier looked to us to design and manufacture a compression spring that provided the same force with centered coils that would stand square.

Master Spring Solution

Customers often come to us when they can’t find a spring vendor to make a challenging spring. In fact, our filter supply customer received several “no quotes” from numerous spring manufacturers. Within an hour of receiving the print, we designed and manufactured a working prototype compression spring with variable diameter and pitch that supported the spring’s load and reduced the number of coils and the amount of wire used in production. We delivered the prototype to the filter supplier within 24 hours of their first contact with us.

Results

By reducing the number of coils and the outside diameter of some coils, we manufactured an extreme hourglass-shaped compression spring using less wire. Since the compression springs are bowl-fed to automatically drop into the fuel canister, the compression spring must position itself in the upright position. If either cut-off end of the spring sticks up even slightly—or if any coil overlaps another coil and sticks together—the spring will puncture the canister. To prevent these issues, our team angled the spring’s cut-off ends down slightly. The coils are centered and standing up square even though there are not many coils. In addition, Master Spring developed a custom packaging solution for this customer that made assembly faster and safer. Originally, these compression springs were shipped in heavy barrels that required two assembly line workers to safely lift. Our custom packaging solutions created a system in which each shipment is packaged in custom boxes with an exact weight that one assembly worker can easily lift—saving assembly time and creating a safer work environment.

Need a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.