Get unique, complex parts easily. No matter your requirements, Master Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Master Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

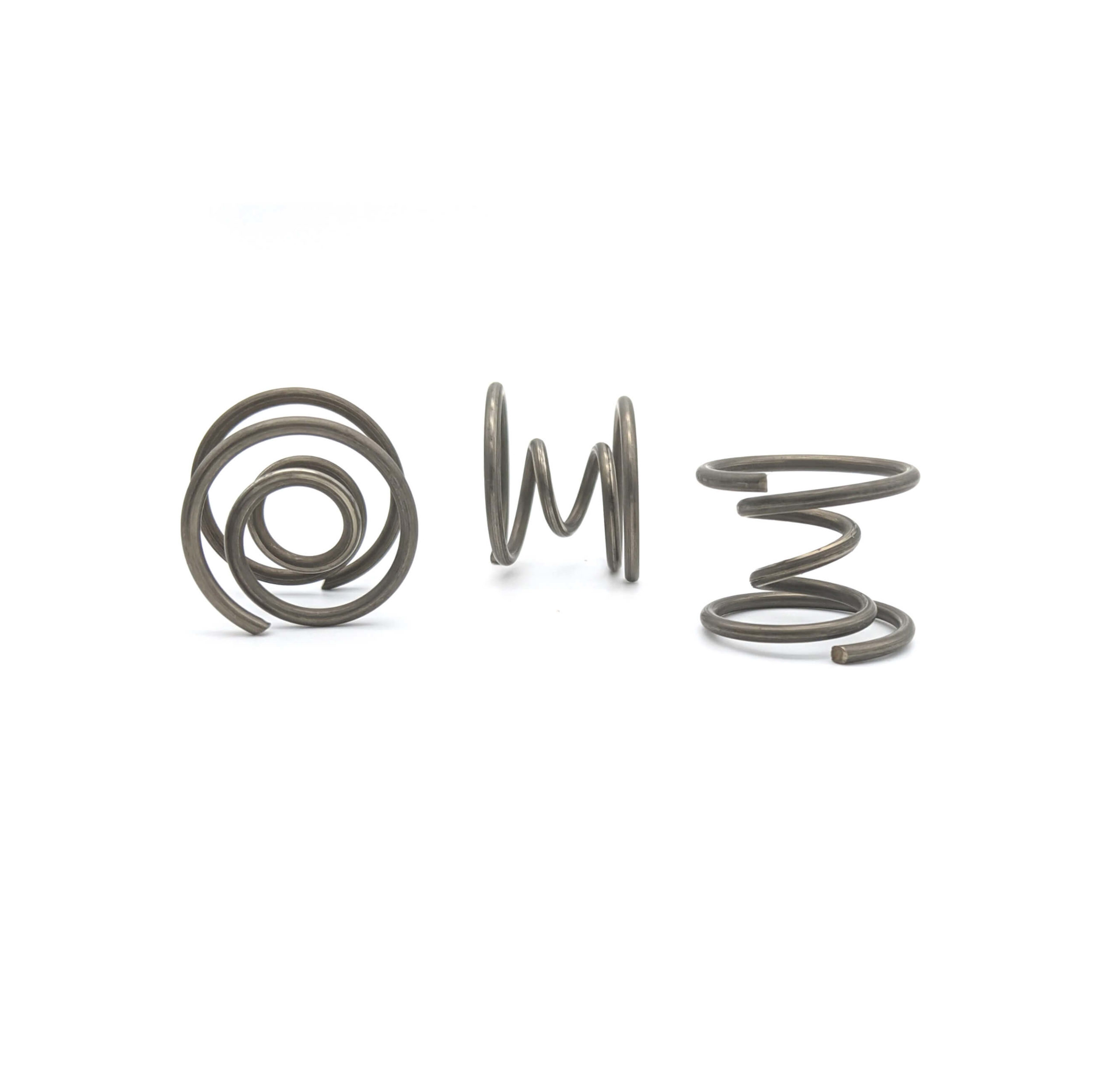

Master Spring custom manufactures complex, made-to-order compression springs from round wire, including solenoid valve springs, contact springs, filter springs, clamp springs, conical springs, ball plunger springs, light duty compression compression springs and more.

Fuel Dispenser Filter Spring

Part Names: Hourglass compression spring, fuel filter spring, petroleum filter canister coil spring

Industry: Filters for the petroleum, industrial, agricultural, heavy duty, and biofuel markets

Application: Spring holds media in place inside canister

Material: 0.099” hard-drawn bright wire

Special Features: Hourglass-shaped spring; no overlap on ends; packed 1,000 springs per box

Conical Valve Spring

Part Names: Solenoid valve spring, solenoid spring, conical valve spring, CEG conical compression spring

Industry: Solenoid valves

Application: Compression spring is used inside solenoid valves that control critical flow of air, gas, water, oil or steam

Material: 0.135” phosphate-coated music wire

Special Features: Closed ends and ground; zinc plate

Lockout Bar Spring

Part Names: Small compression spring, CEG compression spring, lockout bar spring

Industry: Construction power tools

Application: Prevents unwanted nailing gun cycling when nail magazine is empty

Material: 0.010” stainless steel 302 wire

Special Features: Closed ends and ground; packed 500 parts per bag

Spiral Reinforcement

Part Names: Coiled rebar, conical rebar, concrete spiral reinforcement

Industry: Hardware and fasteners: Railroad track systems

Application: Acts as rebar in railroad concrete sleepers

Material: 0.236” cold-rolled C1008 bright basic wire

Special Features: Coils must be concentric and must screw onto mating part

Contact Spring

Part Names: Electric contact spring, conical spring, stainless steel conical compression spring

Industry: Kitchen and bathroom faucets

Application: Contact spring for touch-on, touch-off and hands-free faucets

Material: 0.024” Stainless Steel 302 Wire

Special Features: Conical spring with bottom end kicked in. Closed ends and not ground. Packed on tack board to prevent tangling.

Spout Spring

Part Names: Stainless steel compression spring, stainless CENG compression spring, flow control button spring

Industry: Hardware and fasteners: Portable plastic fuel containers

Application: Flow control button for pouring gas

Material: 0.059” stainless steel 302 wire

Special Features: Closed ends and not ground

Load More

As an industry-leading compression springs manufacturer, we are your one-stop source for precision, custom compression springs in a wide range of spring body shapes and wire sizes. Learn about our extensive compression spring production services—from grinding to rapid prototyping, special packaging, assembly services and more.

QUICK CHANGES TO BODY SHAPES

SPRING GRINDING CAPABILITIES

ENGINEERING SUPPORT

SPECIAL PACKAGING

ASSEMBLY SERVICES

DOCUMENTATION, CERTIFICATES AND COMPLIANCE

WIRE DIAMETER RANGE

WIRE MATERIAL TYPES

COMPRESSION SPRING FINISHINGS

CUSTOMER SUCCESS STORY

With expert engineering assistance, coiling machines that can easily change spring body shapes, in-line camera monitoring and sorting, and the latest design software tools, we make it possible to manufacture complex, custom compression springs.

Learn More About UsCUSTOMER-FOCUSED COLLABORATION

STATE-OF-THE-ART MACHINES

CURRENT TECHNOLOGY FOR INCREASED EFFICIENCY

Need a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.