Get unique, complex parts easily. No matter your requirements, Master Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Master Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

With over 75 years of manufacturing experience, Master Spring is a proven U.S. supplier of wire forms and coil springs for the electronics industry.

We manufacture wire forms and springs for battery contacts, solenoid valves, antennae, heating elements, heat sink clips, electronic games and electronic equipment.

Battery Connector

Part Names: Coiled battery contact spring, nickel plated coil battery spring

Industry: Electronics

Application: Coil spring battery contact

Material: 0.028” phosphate-coated music wire

Special Features: Electroless nickel plate, packed on tack boards to prevent tangling

Spring Clip

Part Names: Heat sink clips, PCB spring clips, wire form clips

Industry: Electronics

Application: Spring clip quickly and securely mounts heat sinks to a wide range of electronics packages, including: BGA, QFP, LCC, LGA, CLCC, TSOP, DIPs and LQFP components without needing to drill holes in the PCB

Material: 0.033” stainless steel 302 wire

Special Features: Individually packed in heat sealed bags and labeled

Contact Spring

Part Names: Electric contact spring, conical spring, stainless steel conical compression spring

Industry: Kitchen and bathroom faucets

Application: Contact spring for touch-on, touch-off and hands-free faucets

Material: 0.024” Stainless Steel 302 Wire

Special Features: Conical spring with bottom end kicked in. Closed ends and not ground. Packed on tack board to prevent tangling.

Conical Valve Spring

Part Names: Solenoid valve spring, solenoid spring, conical valve spring, CEG conical compression spring

Industry: Solenoid valves

Application: Compression spring is used inside solenoid valves that control critical flow of air, gas, water, oil or steam

Material: 0.135” phosphate-coated music wire

Special Features: Closed ends and ground; zinc plate

Agitator Motor Heater Spring

Part Names: Stainless steel extension spring, heating element extension spring, German loop extension spring

Industry: Beverage dispensing and cooling equipment

Application: Extension spring works as a heating element to keep ice agitator motor warm in beverage dispensing equipment

Material: 0.025” type 302 stainless steel wire

Special Features: German closed loops in-line

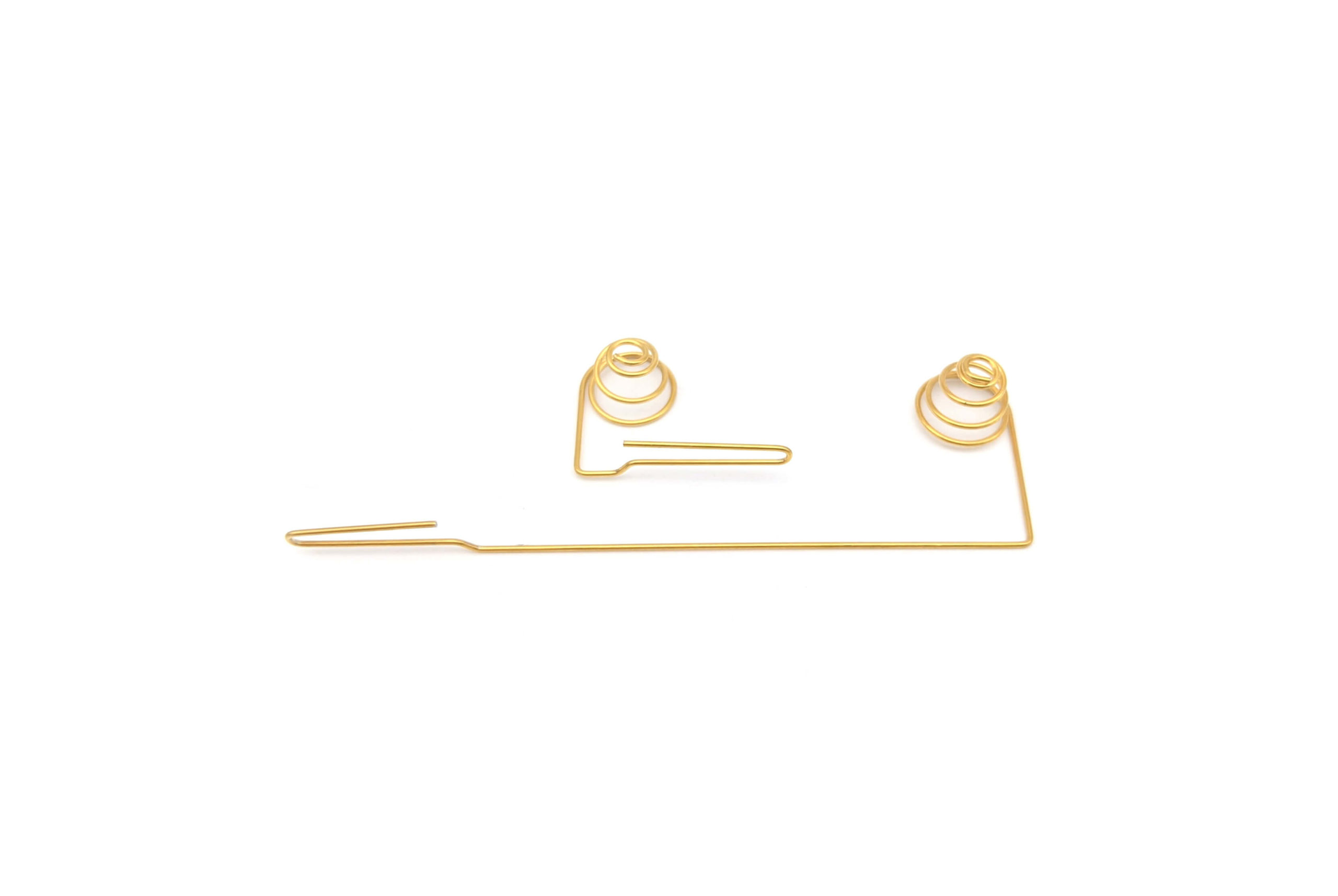

Electrical Contact Spring

Part Names: Battery terminal spring contact, gold plated stainless steel electrical contact, coil spring contact

Industry: Electronics

Application: Coil spring battery contact in medical diagnostic equipment

Material: 0.028 gold pre-plated stainless steel 302 wire

Special Features: Gold-plated wire; packed three stacks of five nested pieces per ziplocked bag

Load More

Together We Achieved

Customer Wire Form Challenge

The spring clips are an integral part to the heat sink’s functionality. The spring clip has multiple bends, and the two sides must be mirror images of each other for the product to work correctly. Each spring clip is bagged and labeled so it can be packed unassembled with the OEM’s product. The OEM’s customers assemble the spring clip to the heat sink and to their printed circuit board. If a spring clip were out of tolerance, the OEM’s customer would find out first as opposed to on the OEM’s assembly line. Therefore, the OEM requires precise wire forming and packaging with near zero defects.

Master Spring Solution

Master Spring’s CNC wire forming machines with laser sensors monitor the multiple bends of these clips to ensure the two sides of the clip meet precise tolerances. Once formed, each spring clip is individually packed in a pre-labeled, heat-sealed bag that is ready to include in direct shipments.

Results

Because of Master Spring’s precise wire forming and packaging solution, our OEM customer can easily include a labeled and bagged wire form spring clip with every heat sink they ship. They know their wire form will work every time the end user opens the bag and assembles the clip to the heat sink.

Together We Achieved

Customer Extension Spring Challenge

Our customer, a gaming and pinball manufacturer, used drop-target extension springs with side loops for their pinball machines. Although this spring design worked, it had a short life cycle. Our customer needed assistance designing a quality spring that would last.

Master Spring Solution

This extension spring showcases Master Spring’s design expertise and finishing capabilities. Upon seeing how one side loop experienced excess stress, our engineer recommended making one single side loop into a double loop at a 45-degree angle. This angle stopped the distorted movement and stress, and the double loop increased the spring’s strength. Additionally, to achieve an error-free assembly, Master Spring applied red dye to the 45-degree double looped end. The assembly operators could easily identify the angled loop and assemble it correctly.

Results

By redesigning the loop on one side of the extension spring, Master Spring manufactured an extension spring with less distortion, less cracking and a longer life cycle. We achieved error-free assembly by dyeing one end of the spring red to help the assembler easily identify which looped end to install to the target assembly.

Need a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.