Get unique, complex parts easily. No matter your requirements, Master Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Master Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

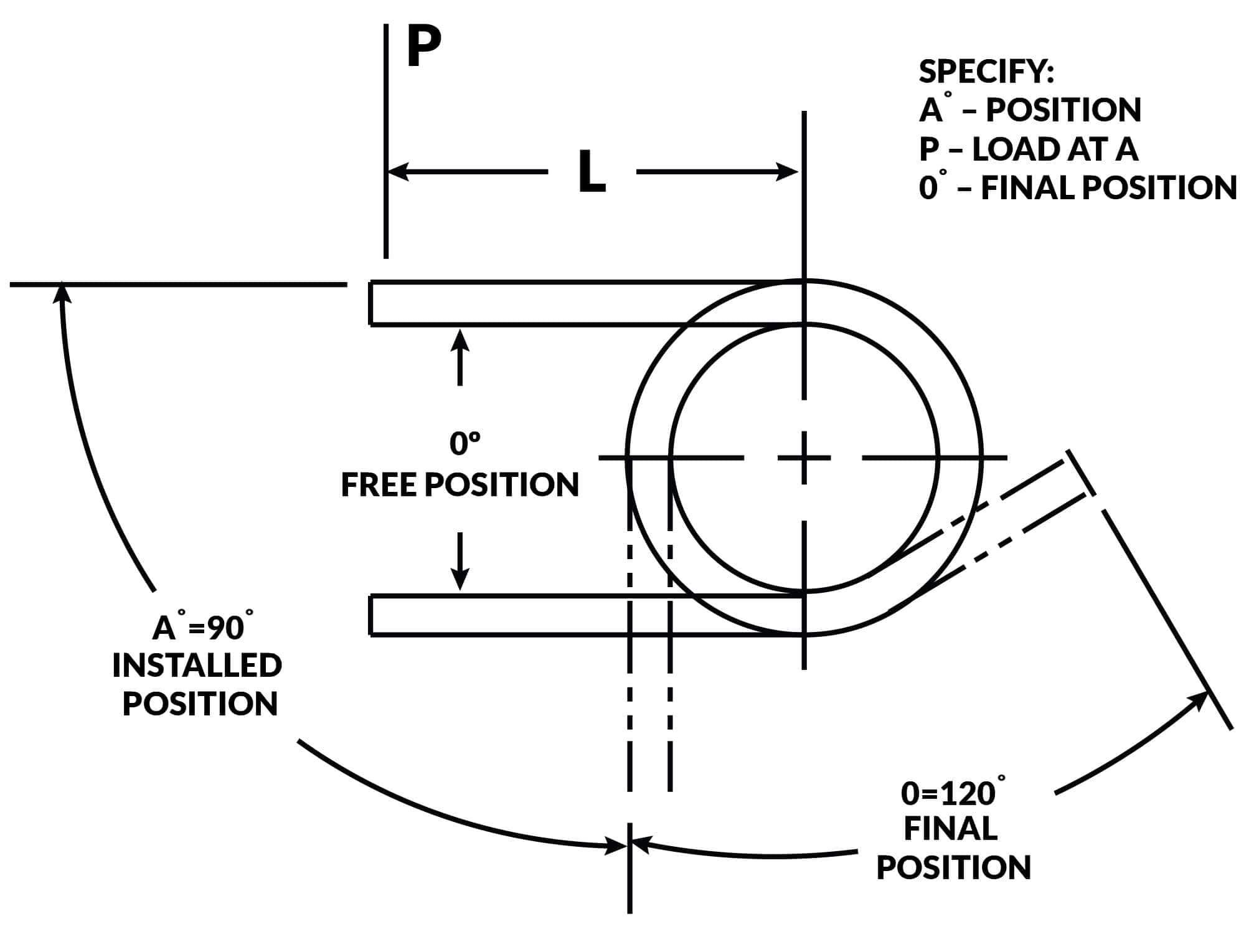

Explore the information below to find technical advice on torsion spring design, such as how to specify leg position and load requirements, common torsion leg configurations, and wire diameter sizes that we can form into large or small torsion springs.

Contact Us

The diagram to the left shows how to specify leg position and corresponding load requirements for a torsion spring.

Load and deflection requirements for torsion springs include:

You can use common torsion spring specifications to find important measurements, including inner diameter, outer diameter, leg length, body length, and more.

What information does Master Spring need to quote your torsion spring? Download the checklist to make sure you specify the critical dimensions of your custom torsion springs. For help with your torsion spring design, please call us at 708-453-2570.

Download the ChecklistTorsion Spring Wire Diameter

Single and Double Torsion Spring Materials

End or Leg Configurations of Torsion Springs

Double Torsion Springs Design Recommendations