Get unique, complex parts easily. No matter your requirements, Master Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Master Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

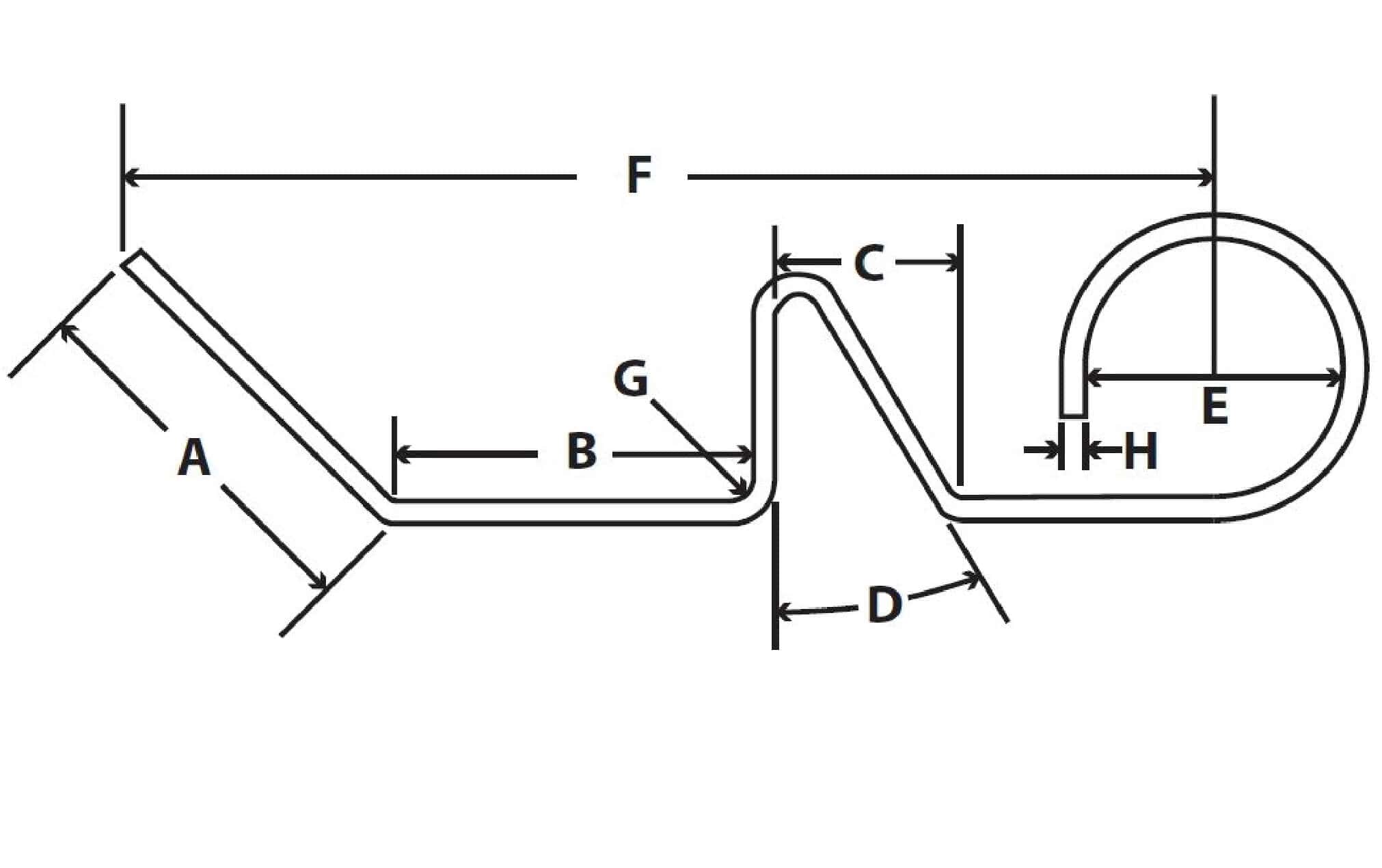

Explore the information below to find technical advice on wire forms, including how to specify dimensions for your wire form, how to calculate the radius of a wire form, and what ranges of wire diameter can be formed.

Contact Us

The diagram and notes describe how to specify dimensions for wire forms. We have shown our preferred ways to specify dimensions to make it easier to inspect and produce your part.

Please refer to the legend below in regards to the wire form dimensions diagram:

Wire Diameter

Wire Form Material Type

Need a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. Please attach a PDF or CAD file with your request to quote.